Extended Professional Insights on Aluminum Column Cladding

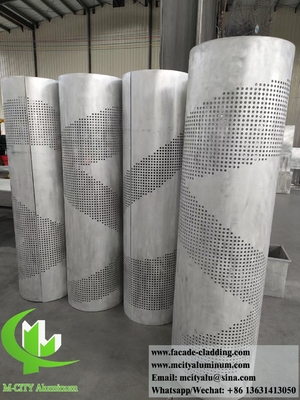

Beyond its core advantages in material, structure, and performance, aluminum column cladding distinguishes itself through advanced customization capabilities that cater to the most intricate architectural visions—an attribute that has solidified its position as a preferred choice for designers seeking both functionality and uniqueness. Modern manufacturers of aluminum column cladding leverage state-of-the-art digital design tools, such as 3D modeling and parametric design software, to translate abstract concepts into tangible, precision-engineered cladding solutions. For instance, columns with curved or tapered profiles—common in contemporary cultural buildings like museums or art galleries—can be outfitted with aluminum cladding panels that are thermoformed to match the exact curvature of the structure, ensuring a seamless fit that enhances the building’s fluid, organic aesthetic. Additionally, aluminum column cladding supports intricate surface textures, from brushed metallic finishes that add subtle depth to embossed patterns that mimic natural materials like stone or brick. These customization options are not merely cosmetic; they allow architects to align the cladding with the building’s narrative—whether it’s a tech campus emphasizing innovation through sleek, matte-finish aluminum column cladding or a residential community evoking warmth through wood-textured cladding.

Another critical aspect that underscores the professionalism of aluminum column cladding is its adherence to global industry standards and certifications, which guarantee consistency, safety, and performance across projects. In North America, aluminum column cladding must comply with standards set by the American Architectural Manufacturers Association (AAMA), including AAMA 2605 for high-performance organic coatings—ensuring that the cladding resists fading, chalking, and corrosion under rigorous testing. In Europe, the cladding adheres to EN 14782, which specifies requirements for aluminum composite panels used in construction, and must meet fire safety standards such as EN 13501-1, which classifies building products based on their reaction to fire. Additionally, leading manufacturers of aluminum column cladding obtain third-party certifications such as ISO 9001 (quality management) and ISO 14001 (environmental management), demonstrating their commitment to producing reliable, eco-friendly products. These certifications are not just formalities; they provide reassurance to architects, contractors, and building owners that the aluminum column cladding will perform as intended, reducing the risk of costly failures or safety hazards down the line. For example, a hospital construction project requiring fire-resistant materials can rely on aluminum column cladding certified to EN 13501-1 Class A2-s1, d0—indicating low smoke emission and no flaming droplets—ensuring compliance with strict healthcare building codes.

Real-world application cases further illustrate the versatility and value of aluminum column cladding in addressing complex architectural challenges. One notable example is the renovation of a 1920s heritage bank building in downtown Chicago, where the original marble columns had suffered significant weathering and structural damage. The project team opted for aluminum column cladding custom-colored to match the marble’s warm, veined appearance—using high-resolution digital scanning to replicate the marble’s texture on the cladding’s powder-coated surface. The aluminum cladding not only restored the building’s historical charm but also added a protective layer that prevents further deterioration, extending the columns’ lifespan by an estimated 30 years. Another case is the construction of a luxury beachfront hotel in Dubai, where aluminum column cladding with PVDF coating was chosen to withstand the harsh coastal environment. The PVDF coating’s resistance to saltwater corrosion and UV radiation ensured that the cladding retained its crisp, white finish despite constant exposure to sand, salt, and intense sunlight—eliminating the need for frequent repainting and reducing maintenance costs by 60% compared to traditional steel cladding. In a modern office tower in Singapore, aluminum column cladding was integrated with LED lighting systems, transforming the columns into dynamic design elements that illuminate the building’s lobby with soft, color-changing light. This integration was made possible by the cladding’s modular design, which allowed for the seamless installation of lighting fixtures between panels—showcasing how aluminum column cladding can go beyond functional protection to become a central part of a building’s visual identity.

The adaptability of aluminum column cladding to emerging construction trends is yet another factor that reinforces its relevance in the industry. As modular construction gains traction—driven by the need for faster, more efficient building processes—aluminum column cladding has evolved to align with this trend. Manufacturers now offer pre-assembled aluminum column cladding modules, where panels, insulation, and fastening systems are pre-installed in a controlled factory environment before being shipped to the construction site. This not only reduces on-site installation time by up to 40% but also ensures higher quality control, as modules are tested for fit and performance before delivery. Additionally, as smart buildings become more prevalent, aluminum column cladding is being integrated with IoT (Internet of Things) sensors that monitor temperature, humidity, and structural stress—providing real-time data to facility managers and enabling proactive maintenance. For example, sensors embedded within the cladding can detect changes in temperature that indicate insulation gaps, allowing for timely repairs that maintain the building’s energy efficiency.

In terms of cost-effectiveness, aluminum column cladding offers long-term value that extends beyond its initial purchase price. While the upfront cost of aluminum cladding may be higher than that of wood or steel, its low maintenance requirements, long lifespan, and energy-saving benefits result in a significantly lower total cost of ownership over time. A cost analysis conducted by a leading construction consulting firm found that, over a 20-year period, the total cost of aluminum column cladding—including purchase, installation, maintenance, and energy savings—was 35% lower than that of steel cladding and 50% lower than that of wood cladding. This cost advantage is further enhanced by the cladding’s recyclability; at the end of a building’s lifespan, aluminum column cladding can be recycled and repurposed, generating additional value and reducing waste disposal costs. For building owners focused on long-term financial sustainability, aluminum column cladding represents a sound investment that balances upfront costs with long-term savings and environmental benefits.

In summary, aluminum column cladding’s advanced customization capabilities, adherence to global standards, proven real-world performance, adaptability to emerging trends, and long-term cost-effectiveness make it a standout solution in the architectural cladding market. Whether it’s bringing a heritage building back to life, withstanding the rigors of a coastal environment, or integrating with smart building technology, aluminum column cladding consistently delivers on both functional and aesthetic requirements. As the construction industry continues to prioritize innovation, sustainability, and efficiency, aluminum column cladding will remain a key player—empowering architects to create buildings that are not only visually striking but also durable, safe, and eco-friendly.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!